| Place of Origin: | China |

| Brand Name: | Brother Furnace |

| Certification: | CE |

| Model Number: | BR |

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Strong wooden box for global shipping |

| Delivery Time: | 3-21 Working days |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 10000 pcs per month |

| ALUMINA PURITY: | 99.6% | COLOR: | Lvory |

|---|---|---|---|

| SINTERING TEMPERATURE: | 1810℃ | MAX. WORKING TEMPERATURE: | 1800℃ |

| SAG TEMP. UNSUPPORTED TUBE: | 1600℃ | ||

| High Light: | high purity alumina crucibles,engineered ceramics crucibles |

||

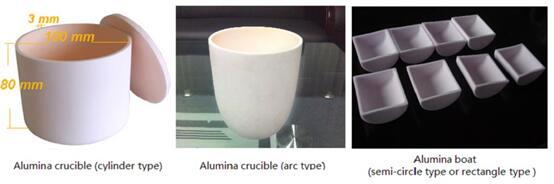

Alumina Ceramic Crucible

High Purity Alumina Crucible, 99.6% Al2O3 Alumina Ceramic Crucible

High purity alumina products can withstand very high temperature under reducing, inert or high vacuum condition. They remain good chemical resistance under high temperature, and have excellent wear and abrasion resistance. Alumina products can withstand up to 1800℃.

● Alumina purity: 99.6%

● Color: Lvory

● Sintering temperature: 1810℃

● Max. working temperature: 1800℃

● Sag Temp. Unsupported Tube: 1600℃

| Chemical Composition (%) | Al2O3 | >99.6 |

| SiO2 | <0.1 | |

| Fe2O3 | <0.05 | |

| R2O | <0.1 |

Standard size:

Alumina crucible

| Capacity (ml) | Specification (mm) | Capacity (ml) | Specification (mm) |

| 5 | Dia20x25x2 | 250 | Dia65x80x3 |

| 10 | Dia29x33x2.5 | 280 | Dia65x105x3 |

| 20 | Dia34x38x2.5 | 300 | Dia85x60x3 |

| 30 | Dia38x44x2.5 | 320 | Dia70x100x3 |

| 40 | Dia42x45x2.5 | 400 | Dia90x90x4 |

| 50 | Dia45x48x2.5 | 450 | Dia80x115x3.5 |

| 60 | Dia47x47x2.5 | 600 | Dia85x130x3.5 |

| 70 | Dia50x55x2.5 | 750 | Dia91x140x3.5 |

| 80 | Dia50x56x2.5 | 800 | Dia95x135x4 |

| 100 | Dia52x60x2.5 | 900 | Dia95x160x5 |

| 120 | Dia45x120x2.5 | 950 | Dia100x150x4 |

| 130 | Dia57x66x2.5 | 1200 | Dia120x120x5 |

| 150 | Dia50x100x2.5 | 1250 | Dia100x200x5 |

| 170 | Dia50x120x2.5 | 2000 | Dia120x260x5 |

| 2500 | Dia155x150x5mm |

Alumina Boat (semi-circle type or rectangle type )

| Capacity (ml) | Specification (mm) |

| 15 | 70x20x15mm |

| 20 | 65x30x17mm |

| 20 | 100x12x15mm |

| 150 | 120x60x25mm |

| 200 | 100x100x27mm |

Other size can be produced according to customer' s requirement.

Note: Alumina products are sensitive to thermal shock. Try to warm up the furnace chamber slowly. A heating rate between 150 ℃~300 ℃/hour is recommended for the first 1-1.5hours, so that the alumina products can be evenly heated to reduce the impact of thermal shock.

Contact Person: li

Tel: +8613526693072